A Division of the Formosa Heavy Industries Corp., Formosa Gear Has the Flexibility to Meet All Your Power Transmission Needs…..

A Division of the Formosa Heavy

Industries Corp., Formosa Gear Has the

Flexibility to Meet All Your Power Transmission Needs…..

Member of the American Gear Manufacturers Association |

ISO 9001 Certified |

Formosa Heavy Industries Corp. Gear Plant

100 Suei-Guan Rd. Jen-Wu, Kaohsiung,Taiwan, R.O.C.

Phone: +886-7-3711838, 3738164

Fax: +886-7-3721748

E-mail: gear-fhi@fpc.com.tw

History of the FHI Gear Plant

Founded for supporting its mother & sister companies, the FHI Gear Plant has been manufacturing world class quality gear products in Taiwan for nearly two decades. In the very beginning, it operated as a gear facility for companies of the Formosa Plastics Group—the largest manufacturing group in Taiwan--, manufacturing gear drives for its own use with applications such as coal pulverizers, cooling tower fans, conveyors, agitators, plastic pelletizers, mixing rolls, calenders and extruders. Also used its surplus capacity to provide high-precision ground gears to then thrive machine tool industry.

Today, with its modern 170,000 square foot facility full of the most state of the art manufacturing equipment and a highly skilled engineering support team, the FHI Gear Plant has become the No.1 gear manufacturer in Taiwan, also one of the best in the world, providing heavy duty gear drives and open gearing to various industries including Steel, Cement, Plastic & Rubber, Petrochemical, Mining and Sugar industry.

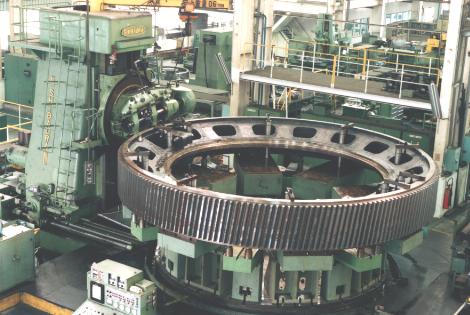

FHI Gear Plant specializes in large, high torque, customized gear drives with output torque up to 4,350,000 ft-lb. We can carburize and precision grind gears up to 98” in diameter and hob gears up to 295” in diameter. Our in-house heat treat department is one of the finest in the world that all precision heat treat processes are controlled by computers. FHI Gear Plant is under license from Renk of Germany and is a technical member of AGMA. FHI Gear Plant achieved ISO 9001 certification in 1994.

Manufacture Equipment and Heat Treatment

The Formosa Gear Plant is equipped with the state of the art machine tools. Most of which are computer numerically controlled for higher efficiencies and accuracy. Formosa can hob gears up to 7.5 meters (295”) in diameter and precision grind gears up to 2.5 meters (98”) in diameter.

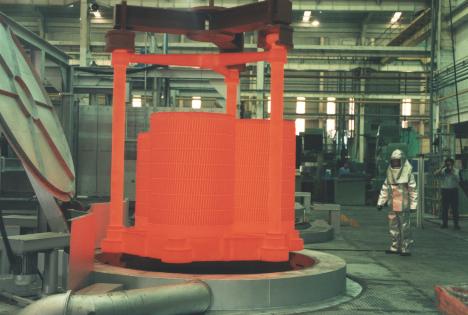

In addition, Formosa performs all the heat treating processes within the Gear Plant. Carburizing, Through Hardening, Induction Hardening and Ion-Nitriding are used to maximize the strength and durability of the gearing.

Formosa Gear produces and supplies gear products designed for maximum reliability and performance. Let Formosa's experience, advanced technology and superior facilities produce for you.

7.5 meter precision hobber

8.4 meter heavy-duty vertical turning lathe

Horizontal pinion hobber

Brand-new 2.5 meter precision gear grinder

Large-scale annealing furnace

Brand-new 2.5 m (d) x 2.5 m (h) carburizing furnace

Induction Hardening

List of Equipment / Main Facilities

| Turning | |

| O-M VT5-12N | 1350 (53”) O.D. x 1250 (49”) High |

| Toshiba TSS-20/40 | 4000 (158”) O.D. x 2000 (79”) High |

| Toshiba TMD-13 | 1600 (63”) O.D. x H1100 (43”) High |

| Boring & Milling | |

| Mitsubishi MAF RS-150B-NC |

X=8000 (315”) Y=2500 (98”) Z=700 (28”) W=900 (35”) V=1000 (39”) |

| Mitsubishi MAF 200/260-NC |

X=16000 (630”) Y=5000 (197”) Z=1200 (47”) W=1200 (47”) V=1500 (59”) |

| Toshiba 11R16 B.T.D. |

X=2000 (79”) Y=1500 (59”) Z=1450 (57”) W=500 (20”) |

| Mitsubishi M-VR 28/32A |

X=8950 (352”) Y=3900 (154”) Z=1000 (39”) W=950 (37”) |

| Gear Hobbing | |

| Pfauter PE1600 | 1600 (63”) O.D. x 1000 (39”) High |

| Pfauter P900 | 970 (38”) O.D. x 500 (20”) High |

| Pfauter P250H | 300 (12”) O.D. x 2000 (79”) Long |

| Schiess RFW 10S | 1400 (55”) O.D. x 3350 (130”) Long |

| Liebherr L-1800 | 1800 (71”) O.D. x 600 (24”) High |

| Karatsu GH-20 | 4270 (168”) O.D. x 900 (35”) High |

| Toshiba HHA-750A | 7500 (295”) O.D. x H3300 (130”) High |

| Gear Grinding | |

| Hofler H2504 | 2500 (98”) O.D. x 750 (30”) High |

| Hofler H1253 | 1250 (49”) O.D. x 750 (30”) High |

| Hofler H1601 | 2000 (79”) O.D. x 550 (22”) High |

| Hofler H1000 | 1000 (39.4”) O.D. x 298 (12”) High |

| Hofler H630-A | 670 (26.4”) O.D. x 240 (9.4”) High |

| Reishauer RZ362A | 360 (14.2”) O.D. x 175 (6.9”) High |

| Reishauer AZA21 | 330 (13”) O.D. x 180 (7”) High |

| Reishauer AZA20 | 330 (13”) O.D. x 180 (7”) High |

| Gear Shaping | |

| Maag 180/300 | 2900 (114”) O.D. x 220 (8.7”) High |

| Karatsu GH-20 | 4800 (189”) O.D. x 120 (4.7”) High |

| Lorenz LS420 | 470 (18.5”) O.D. x 100 (3.9”) High |

| Gear Shaving | |

| Red Ring GCU-8”/12” |

489 (19.3”) O.D. x 127 (5”) High |

| Spiral Bevel | |

| Klingelnberg AMK 630 |

650 (25.6”) O.D. x Mn13 |

| Klingelnberg LKR 631 |

650 (25.6”) O.D. x Mn13 |

| Grinding | |

| MWM SA6/1U | 515 (20.3”) O.D. x 3000 (118”) Long |

| Toyoda Gop32*100 | 320 (12.6”) O.D. x 1000 (30.8”) Long |

| Sielemann RB130 | 1300 (51.2”) O.D. x 610 (24”) Long |

| Kapp KS803 | 300 (11.8”) O.D. x 800 (31.5”) Long |

| Toyo T-1253 | 300 (11.8”) I.D. x 300 (11.8”) Long |

| Okamoto TGM-2M | 200 (7.9”) I.D. x 200 (7.9”) Long |

| Heat Treating | |

| Aichelin VBEK 250/250 Carburizing Furnace |

2500 (98.4”) O.D. x 2500 (98.4”) Long |

| Aichelin VRBE 130/200 Carburizing Furnace |

1300 (51.2”) O.D. x 2000 (78.4”) Long |

| Aichelin VKES 70/65/130 Carburizing Furnace |

W750 (29.5”) x H650 (25.6”) x L1300 (51.2”) |

| Aichelin VHE 50/300 Gas Nitriding Furnace |

500 (19.7”) O.D. x 3000 (118.1”) Long |

| Klockner G160 Ion Nitriding Furnace |

600 (23.6”) O.D. x 9000 (354.3”) Long |

| Klockner G450 Ion Nitriding Furnace |

1800 (70.9”) O.D. x 3500 (137.8”) Long |

| Aichelin DELS 80/50/120 High Temp. Furnace |

W850 (31.5”) x H500 (19.7”) x L1200 (47.2”) |

| DAI-ICHI H. F. 180 kw Induction Hardening |

8 KHz x 180 kw |

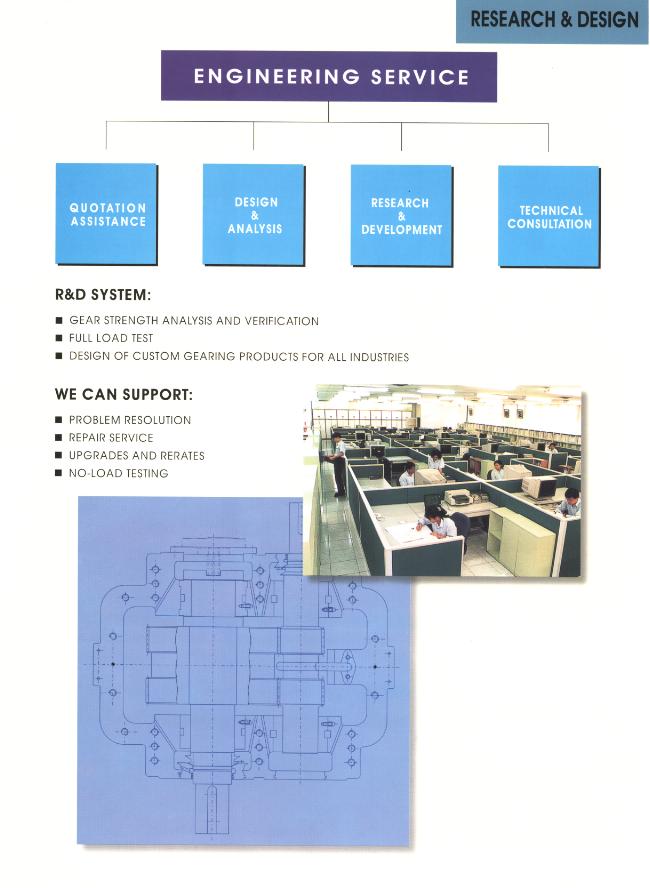

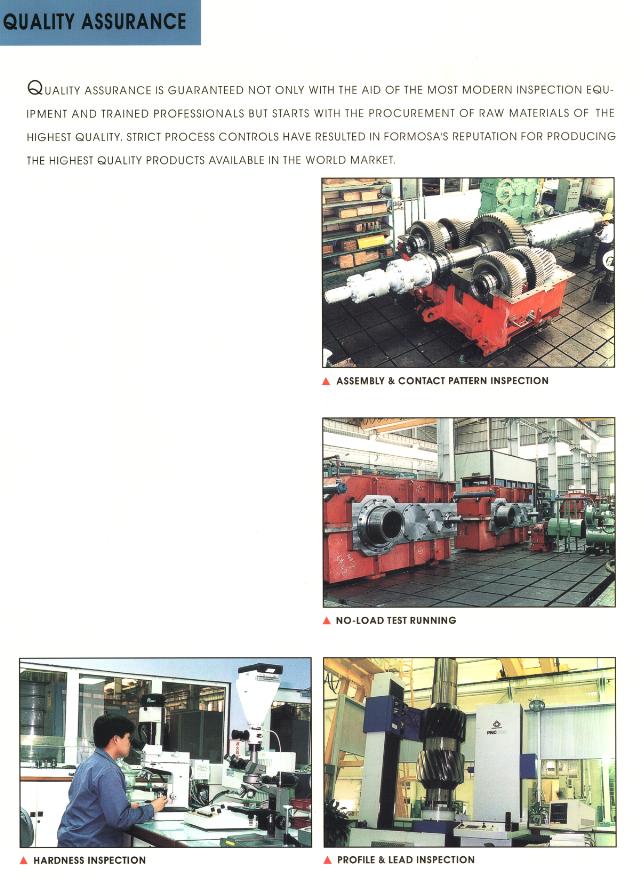

ENGINEERING SERVICE

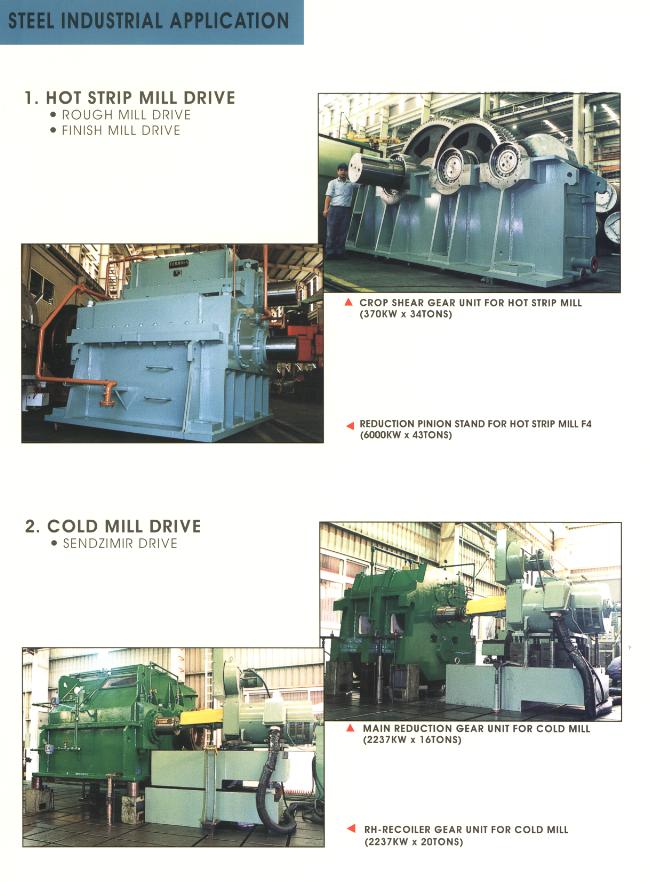

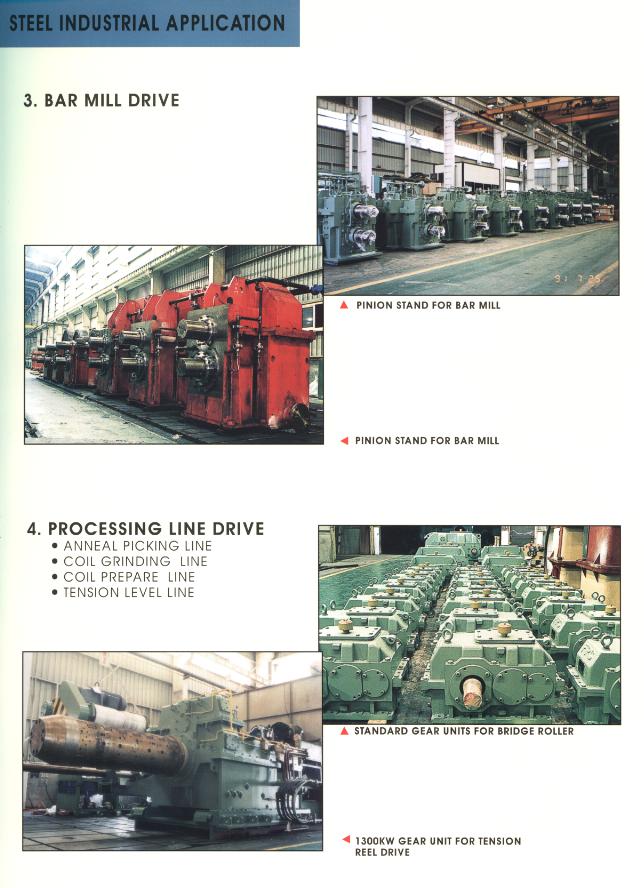

Steel Industry Application

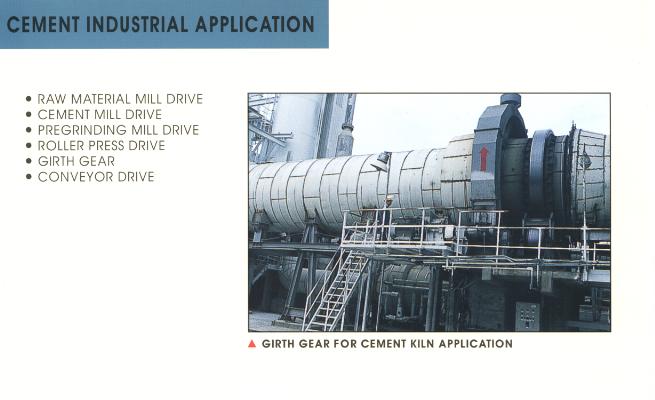

Cement Industry Application

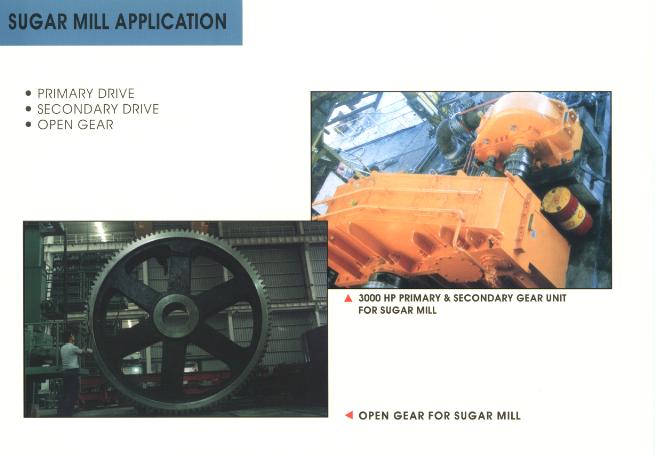

Sugar Mill Application

Plastic and Rubber Application

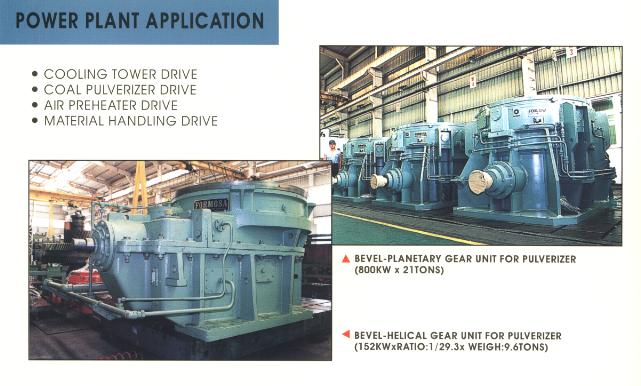

Power Plant Application